Applications / Industries

Aviation/Aerospace Industry

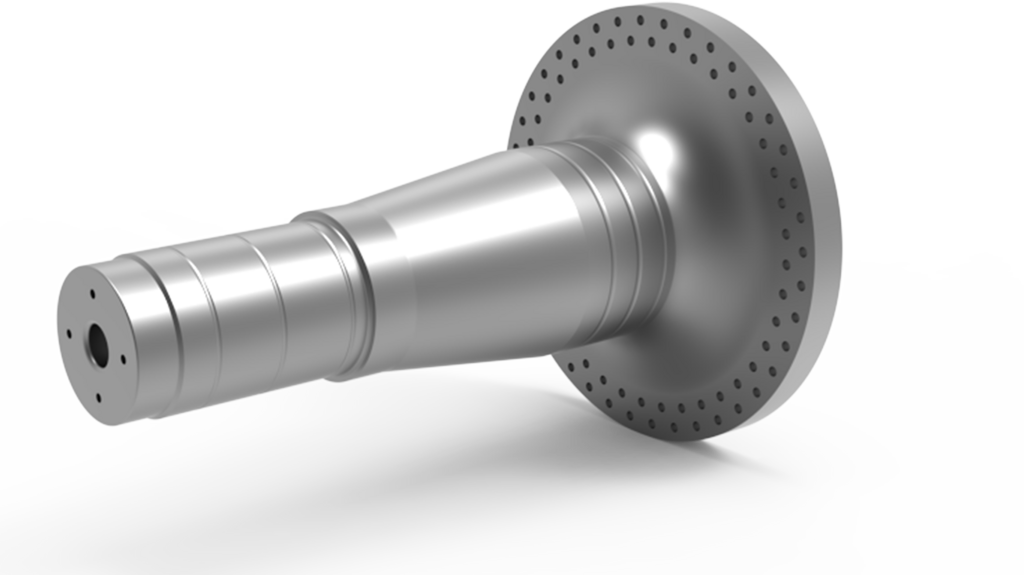

In the demanding realm of aviation and aerospace, precision and reliability are paramount. Weingärtner'smpmc machines are engineered to meet these exacting standards, making them the ideal choice for producing critical components such as landing gears, turbine shafts, engine casings, compressor discs, blades and vanes for turbines, and other complex workpieces integral to aircraft performance and safety.

Our state-of-the-art mpmc machines offer unparalleled precision, ensuring each part meets the stringent tolerances required in aerospace applications. Furthermore, our advanced technology enhances production efficiency and reduces lead times, enabling you to maintain a competitive edge in the industry.

Choose Weingärtner for your aerospace manufacturing needs and benefit from our commitment to quality, innovation, and excellence in every workpiece we help you create.

Oil & Gas Industry

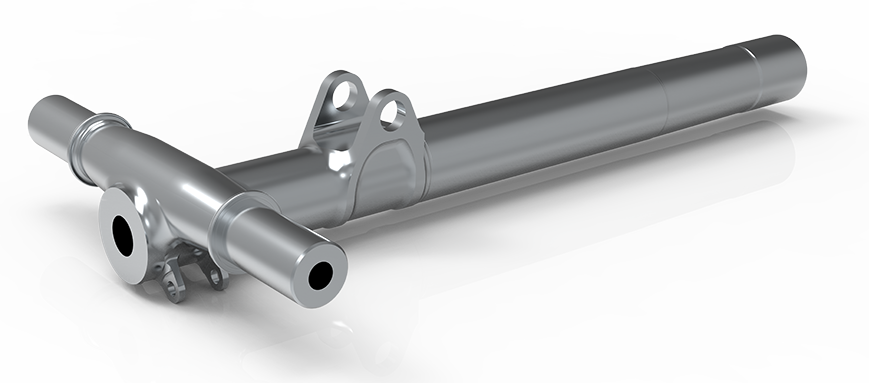

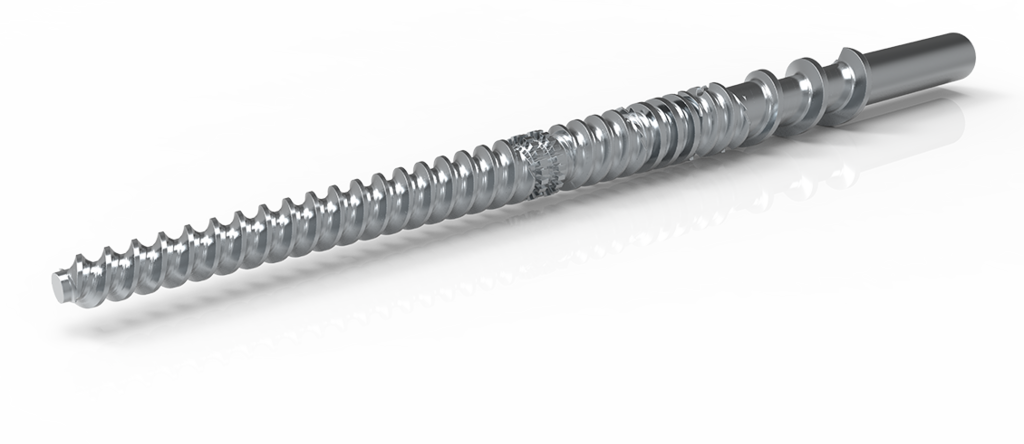

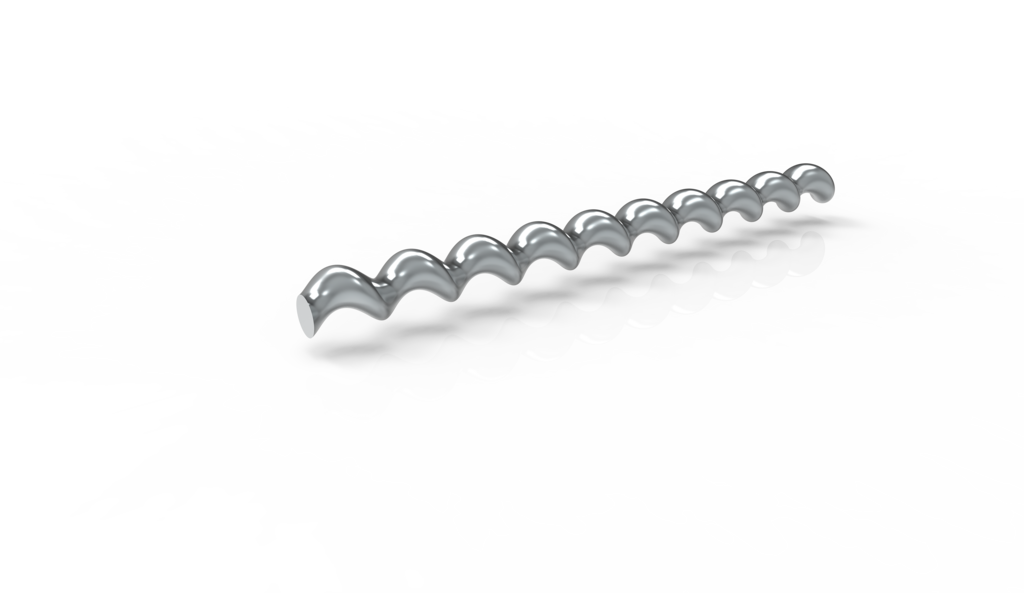

In the critical oil and gas industry, where durability and precision are essential, Weingärtner's range of machines—including the mpmc, vario⁺, and finish — are expertly designed to meet these high standards. The oil and gas sector, responsible for over half of the world's energy supply, demands the utmost reliability from its components. Our machines are ideal for producing vital parts such as rotor pump shafts (single-, double-, and multi-lobe shafts), gas turbines, valve blocks, stabilizers, power section rotors, drill bits, wellhead components, pump and compressor parts, downhole tools, and manifold blocks.

Our versatile mpmc and vario⁺ machines provide a variety of machining methods, including milling, turning, drilling and peeling, ensuring flexibility and precision for your diverse manufacturing needs. Additionally, our finish machines deliver exceptional surface smoothing, meeting the stringent surface quality requirements critical in oil and gas applications.

Choose Weingärtner for your oil and gas manufacturing needs and benefit from our comprehensive machining solutions, innovative technology, and dedication to excellence in every workpiece we help you create. Our machines are engineered to enhance production efficiency, reduce lead times, and maintain the highest quality standards, giving you a competitive edge in the industry.

Plastics Industry

In the dynamic plastics industry, precision and efficiency are key to producing high-quality components that meet stringent standards. The global plastics market is vast, with applications ranging from everyday consumer products to critical components in automotive, medical, and packaging industries. Weingärtner's advanced range of machines—including the mpmc, vario⁺, pickup, and finish—are perfectly suited for this diverse and demanding sector. Our machines excel in producing essential parts such as injection molding screws, extruder screws (single and twin screws), tie rods, cylinders (single and twin cylinders), housings, and other complex workpieces.

Our versatile mpmc, vario⁺ and pickup machines support a variety of machining methods, including turning, milling, drilling and whirling, ensuring the flexibility and precision needed for diverse plastic manufacturing processes. Additionally, our finish machines deliver exceptional surface smoothing, ensuring that each component meets the highest quality standards.

Choose Weingärtner for your plastics manufacturing needs and benefit from our comprehensive machining solutions, innovative technology, and commitment to excellence. Our machines are designed to enhance production efficiency, reduce lead times, and ensure the highest quality standards, providing you with a competitive edge in the ever-evolving plastics industry.

Energy Industry

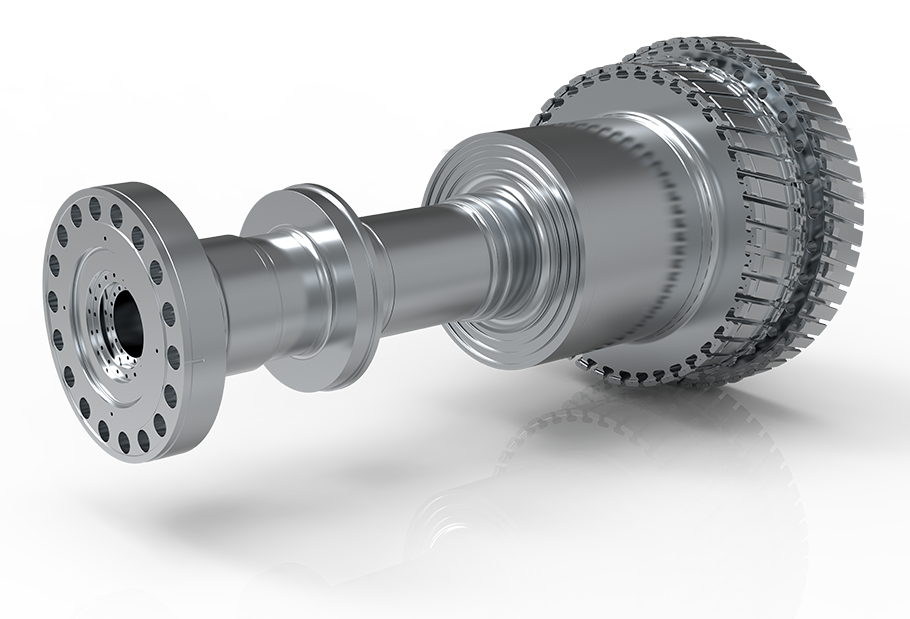

In the rapidly evolving energy sector, where precision and reliability are crucial, Weingärtner's advanced mpmc machine is designed to meet these high standards. The energy industry encompasses a wide range of applications, from traditional power generation to renewable energy solutions, making the demand for high-quality components ever-present. Our machines excel in producing critical parts such as turbine shafts, generator rotors, heat exchanger components, pump impellers, valve bodies, gearbox components, stator and rotor assemblies, and pressure vessel parts.

Our versatile mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision required for diverse energy applications and meeting the stringent quality standards necessary for optimal performance and durability.

Choose Weingärtner for your energy manufacturing needs and benefit from our comprehensive machining solutions, innovative technology, and commitment to excellence. Our machines are engineered to enhance production efficiency, reduce lead times, and maintain the highest quality standards, providing you with a competitive edge in the dynamic energy industry.

Railway Industry

In the railway industry, where safety, durability, and precision are paramount, Weingärtner's advanced range of mpmc machines are expertly engineered to meet these high standards. The railway sector demands high-quality components to ensure the safety, reliability and efficiency of train operations. Our machines excel in producing critical parts such as wheelset axles, brake discs, suspension components, gearbox housings, coupler parts, drive shafts, bogie frames, and railcar body components.

Our versatile mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision needed for diverse railway manufacturing processes, and meeting the stringent quality standards required for optimal performance and safety.

Choose Weingärtner for your railway manufacturing needs and benefit from our comprehensive machining solutions, innovative technology, and commitment to excellence. Our machines are designed to enhance production efficiency, reduce lead times, and ensure the highest quality standards, providing you with a competitive edge in the vital railway industry.

Pump Industry

In the pump industry, where precision and reliability are critical, Weingärtner's advanced range of machines—including the mpmc, vario⁺, and finish—are designed to meet these exacting standards. Pumps play a crucial role in a wide range of applications, from industrial processes to water treatment and oil extraction, necessitating high-quality components for optimal performance. Our machines excel in producing essential parts such as rotor shafts, pump casings, impellers, volutes and sealing components.

Our versatile mpmc and vario⁺ machines support a variety of machining methods, including turning, milling, peeling and whirling, ensuring the flexibility and precision required for diverse pump manufacturing processes. Additionally, our finish machines deliver exceptional surface smoothing, ensuring that each component meets the stringent quality standards necessary for efficiency and durability.

Choose Weingärtner for your pump manufacturing needs and benefit from our comprehensive machining solutions, innovative technology, and commitment to excellence. Our machines are engineered to enhance production efficiency, reduce lead times, and maintain the highest quality standards, providing you with a competitive edge in the demanding pump industry.

Renewable Energy Sector

In the rapidly growing renewable energy sector, precision and reliability are key to advancing sustainable solutions. Weingärtner's mpmc machines are specifically designed to meet the high standards required for this innovative industry. Renewable energy applications demand high-quality components to ensure the efficiency and durability of equipment used in wind, solar, hydro, and other renewable energy systems. Our mpmc machines excel in producing critical parts such as wind turbine shafts, generator rotors, wind propeller shafts, hydro turbine components, gearbox housings, and structural supports.

Our state-of-the-art mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision needed for diverse renewable energy manufacturing processes. These machines deliver exceptional performance and surface smoothing, meeting the stringent quality standards necessary for the renewable energy sector.

Choose Weingärtner for your renewable energy manufacturing needs and benefit from our advanced mpmc machines, innovative technology, and commitment to excellence. Our machines are designed to enhance production efficiency, reduce lead times, and ensure the highest quality standards, providing you with a competitive edge in the progressive renewable energy industry.

General Machining Industry

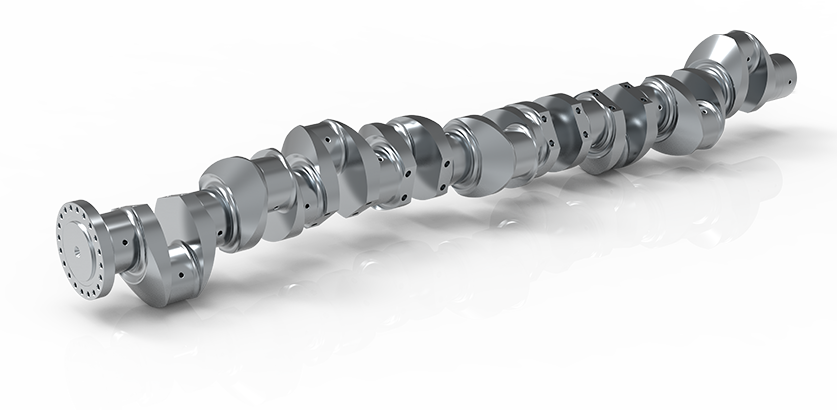

The general machining industry encompasses a wide range of manufacturing applications, requiring versatile and precise machinery to produce high-quality components. Weingärtner's mpmc machines are perfectly suited for this sector, offering exceptional performance and flexibility for various machining tasks. A key specialty within this industry is the production of large crankshafts, critical components used in engines for ships, locomotives, and large industrial machinery.

Our state-of-the-art mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the capability to handle diverse machining needs. These machines are specifically designed to manage the complexity and precision required for producing large crankshafts, delivering exceptional accuracy and surface quality.

Choose Weingärtner for your general machining needs and benefit from our advanced mpmc machines, innovative technology, and commitment to excellence. Our machines are engineered to enhance production efficiency, reduce lead times, and maintain the highest quality standards, providing you with a competitive edge in the diverse general machining industry.