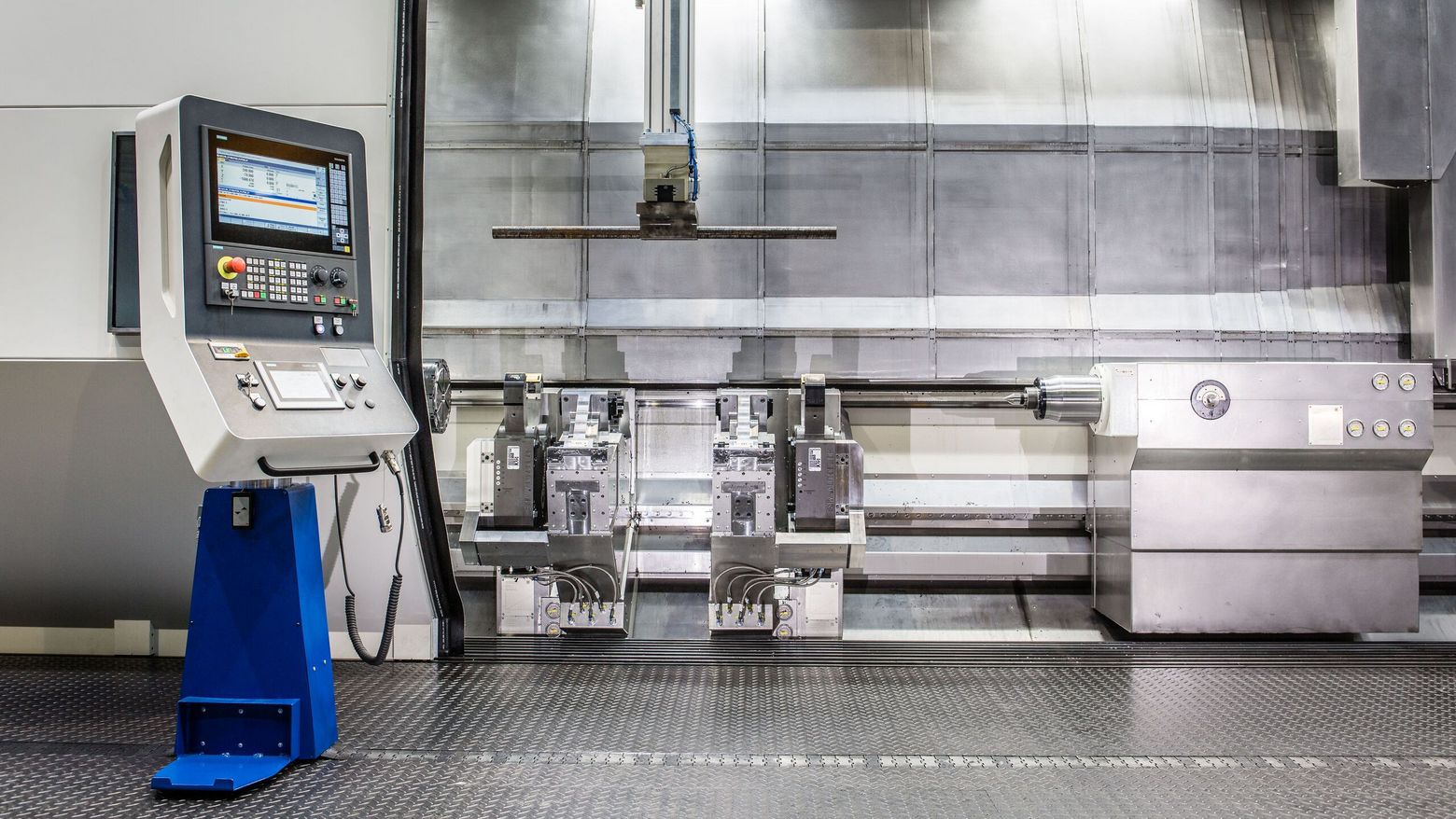

Pickup 400

Advanced Machining Center for Economical Complete Machining of Extrusion and Injection Molding Screws

Introducing the pickup 400, the new generation machine from Weingärtner optimized for the economical complete machining of extrusion and injection molding screws. Building upon the success of the pickup machine series in the plastics industry, this consistent further development is a response to the strong demand from our customers who already utilize the weinCAD Screw-Designer software on Weingärtner machines.

The machine concept is ingeniously simple, combining the "old proven" workpiece clamping concept of the pickup machine series with prism jaw steady rests, a stable headstock, and tailstock, along with the powerful and flexible machining technology of the mpmc turn-mill centers. The result is a highly efficient machining center designed specifically for the complete machining of plastic screws.

The pickup 400 offers our customers significant added value through its integrated system, encompassing programming to the finished workpiece. Existing customers who utilize weinCAD for their screw production can seamlessly transition their program data to the new machine generation, saving valuable time in part programming.

To meet diverse customer requirements, the pickup 400 is available with or without a tool magazine. Standard features of these machines include a completely enclosed work area with emulsion mist extraction, barrier-free access to the workpiece, automatic safety doors, and a rotating and height-adjustable control panel that can be moved along the entire length of the machine.

Experience the pickup 400 and unlock the potential for efficient and precise complete machining of extrusion and injection molding screws. Weingärtner continues to innovate and deliver solutions that enhance productivity and drive success in the plastics industry.